コアテクノロジーが生み出す、

未来の「モノづくり」

日本マタイの研究開発部門では、素材の持つ可能性を引き出し、新たな機能を創造する開発活動を行っています。熱可塑性樹脂の押出・ラミネート・コーティング・印刷加工といったコアテクノロジーを駆使し、お客様の多様なニーズに応える技術革新を推進。開発センターには、小型・大型の試作機や評価機器を備え、開発コストの低減やスピード化を実現する体制を構築しています。さらに、先端技術や新市場のニーズに即応するため、試作機・評価機器の積極的な導入を推進。環境負荷の低減や次世代材料の開発にも注力し、独自性の高い「モノづくり」を追求しています。

研究所 外観

保有設備の一例

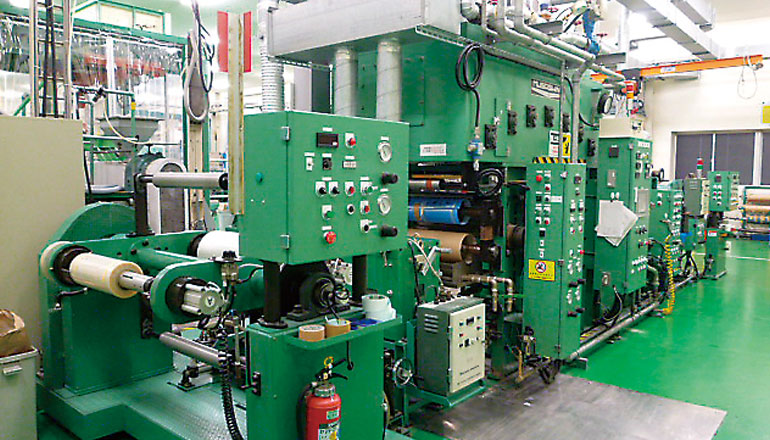

押出ラミネーター

[特長・使用目的]

- 新規ラミネート品の試作

- 樹脂の選定及びサンプル作製

- 最大加工幅:500㎜

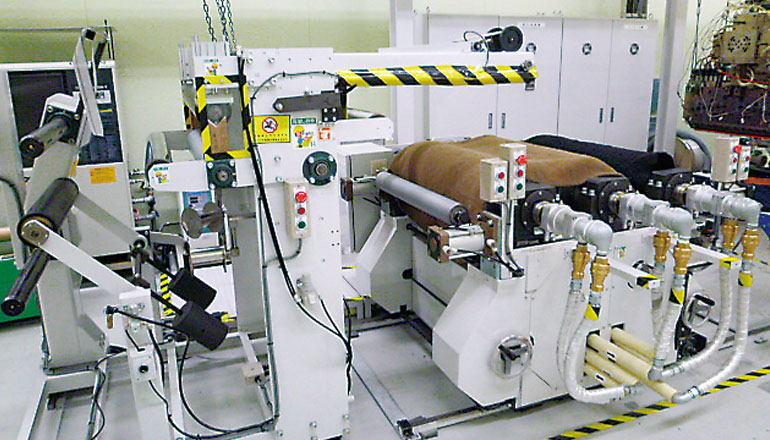

多層フィルム押出機

[特長・使用目的]

- 新規多層フィルム品の試作

- 樹脂の選定及びサンプル作製

- 最大加工幅:500㎜

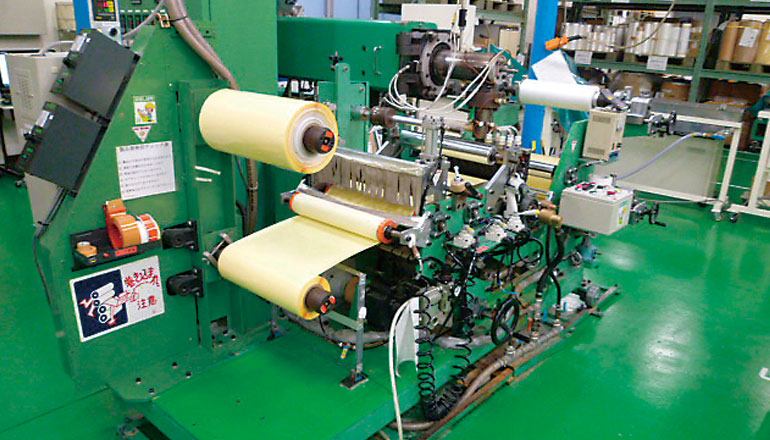

シート押出加工機

[特長・使用目的]

- 新規シート品の試作

- 樹脂の選定及びサンプル作製

- 最大加工幅:300㎜

インフレーションフィルム加工機

[特長・使用目的]

- 新規インフレーションフィルム品の試作

- 樹脂の選定及びサンプル作製

- 最大加工幅:450㎜

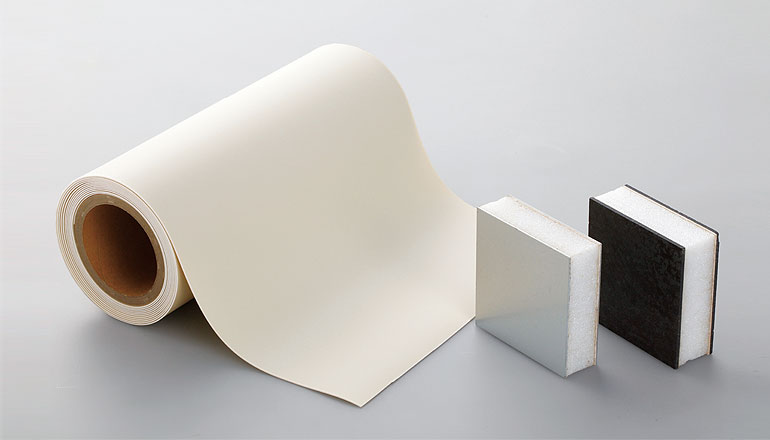

開発品の一例

放射線遮蔽シート

日本マタイ研究所とレンゴー中央研究所とのコラボレーションにより開発したもので、現在も高い空間放射線量を示す地域における実証テストを重ね特許を出願したものです。

低吸着バリアシーラント

汎用のPE系シーラントフィルムとは異なり、水蒸気バリア性、耐薬品性、保香性、低吸着性などの特性に優れ、かつ低パーティクルな環境下で製造した高性能なシーラントフィルムです。