熱可塑性エラストマー樹脂を直接押出成型したシート/フィルムです。カレンダー法や溶液法と異なり溶剤を含まず、環境適合性も優れています。 ABSやPMMAなど加飾フィルム基材にも活用されています。

熱可塑性エラストマーフィルム エスマーURS

特長

- 天然ゴム、合成ゴムの3~5倍摩擦に強く、例えば搬送ベルトなどのような過酷な環境にも耐えます。

- 低温でも硬さが変わりにくく、ゴム弾性が優れているので、極寒地でも冷蔵庫内でも安心して使えます。

- 油やガソリンに対する耐久性が大きく、工業部品、自動車部品、コンテナー、溶剤保護手袋などに好適です。

- 長期間の繰り返し屈曲運動にも優れた耐久性を示し、引き裂きにも強いので、ゴムで解決できない工業部品、コンテナーに適します。

- 織布、不織布、紙、プラスチックフィルムなどと、用途、目的に対応したラミネート加工ができるので、従来、天然ゴム、合成ゴム、軟質塩ビなど、および注型法、カレンダー法、溶液法によるポリウレタン加工で解決できなかったコスト、品質特性の設計ができます。

- 接着の泣き所、軟質塩ビに対してよく付き、靴、サンダルなどの接着についてもウェルダー接着に最適です。

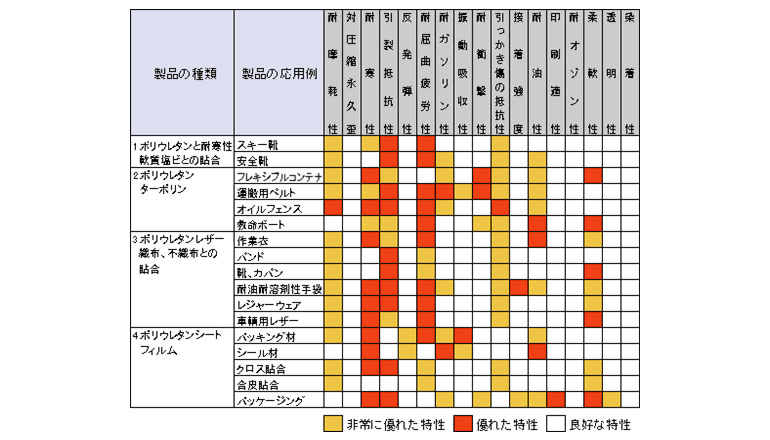

用途・使用例

- 医薬品向けフィルム

- 自動車塗装保護フィルム

- OA機器向け導電性フィルム

応用例

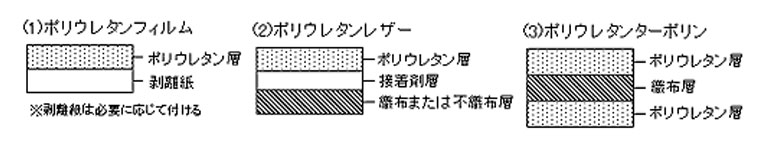

構成例

熱可塑性多層フィルム エスマーMLS

透明性に優れ、熱融着や高周波ウェルダー加工等の二次加工も可能です。

-

特長および用途例

-

- 低比重の材料で、紙、PETから代替する場合に軽量化が図れます。

- リサイクル性が良好です。

- クラス10,000のクリーン環境下で製造しています。

- 紙粉の発生が無い為、クリーンな作業が可能です。

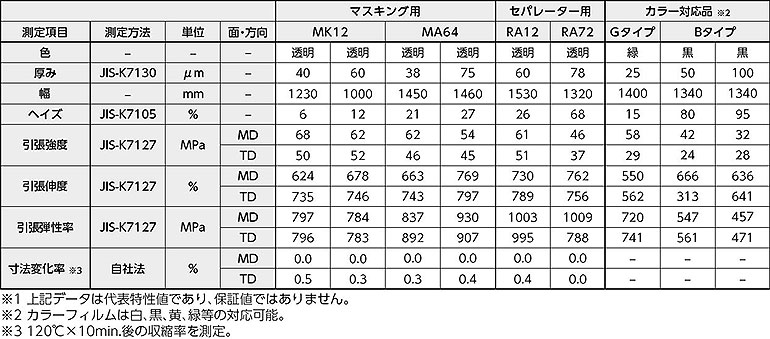

- MK、MAシリーズは、マスキングフィルム用の基材、RAシリーズはセパレーターフィルム用の基材として有用です。

- RAシリーズは薄くて丈夫な材料です。一般CPPフィルムと比較し、伸びが小さく高剛性の為、転写法の粘着加工が可能です。平滑性および透明性に優れます。

- カラー対応品は粘着テープや印刷代替の基材として有用です。比較的小Lotで着色対応は可能です。

- 製品構成によりますが、厚みは最大200μm迄対応可能です。

- 物性・製品規格表※1

熱可塑性多層フィルム エスマーOES

半導体製造のダイシングフィルムとして、クラス1000のクリーン環境で製造しています。

-

特長

- フィッシュアイが少なく、半導体の品質、歩留まり向上に寄与します。

-

用途・使用例

- 半導体工程用ポリオレフィンフィルム

機能性フィルムラインナップカタログ

ホットメルトフィルムや熱可塑性エラストマーフィルムをはじめ、さまざまな機能性フィルムを紹介しています。共押出法によるプロテクトフィルムの特長や、各種フィルムの代表的なグレード他を掲載しています。